KD-KA01

Cecelia is an accomplished electrical engineer with expertise in automation and control systems. She is a natural problem-solver and thrives on developing solutions that optimize performance and efficiency.

Manifold absolute pressure sensor (MAP sensor) is connected to the intake manifold with a vacuum pipe. With different engine speed loads, it senses the vacuum change in the intake manifold and then converts the change in the internal resistance of the sensor into a voltage signal for the ECU to correct the fuel injection volume and ignition timing angle.

In the electronic fuel injection engine, the manifold absolute pressure sensor is used to detect the intake air volume, which is called the D-type injection system (speed density type). The manifold absolute pressure sensor detects the intake air volume not directly like the intake airflow sensor but uses indirect detection. At the same time, it is also affected by many factors, so there are many differences in the detection and maintenance of the intake airflow from the volume sensor. The resulting failure also has its particularity.

The manifold absolute pressure sensor detects the absolute pressure of the intake manifold behind the throttle. It detects the absolute pressure change in the manifold according to the engine speed and load, and then converts it into a signal voltage and sends it to the engine control unit (ECU). The ECU controls the basic fuel injection volume according to the magnitude of the signal voltage.

There are many types of manifold absolute pressure sensors, including varistor type and capacitive type. Because the varistor type has the advantages of fast response time, high detection accuracy, small size, and flexible installation, it is widely used in D-type injection systems.

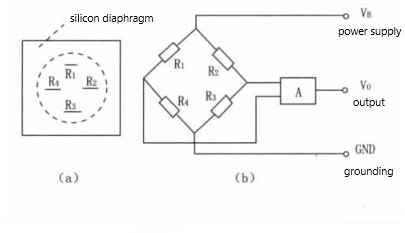

Figure 1 shows the connection between the piezoresistive manifold absolute pressure sensor and the computer. Figure 2 is the working principle of the piezoresistive manifold absolute pressure sensor. The R in Figure 1 is the strain resistor R1, R2, R3, and R4 in Figure 2. They form a Wheatstone bridge and are bonded to the silicon diaphragm. The silicon diaphragm can be deformed under the action of the absolute pressure in the manifold, which causes the resistance value of the strain resistance R to change. The higher the absolute pressure in the manifold, the greater the deformation of the silicon diaphragm and the greater the resistance change of the resistance R. That is, the mechanical change of the silicon diaphragm is converted into an electrical signal, which is then amplified by the integrated circuit and output to the ECU.

The manifold absolute pressure sensor converts the pressure of the engine's intake pipe into a corresponding electrical signal. The engine electronic controller calculates the basic fuel injection time and determines the basic ignition advance angle based on this signal.

Manifold absolute pressure sensors come in many forms. According to the principle of signal generation, they can be divided into piezoelectric, semiconductor varistor, capacitive, differential transformer, and surface elastic wave types.

(1) Measuring principle of semiconductor varistor type

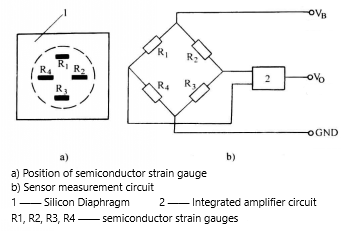

The semiconductor varistor type uses the piezoresistive effect of semiconductors to convert pressure into a corresponding voltage signal. The principle is shown in Figure 3.

The semiconductor strain gauge is a sensitive element whose resistance value changes accordingly when it is under tension or pressure. Attach the strain gauges to the silicon diaphragm and connect them to a Wheatstone bridge. When the silicon diaphragm is deformed by force, each strain gauge is pulled or compressed to its resistance change, and the bridge will have a corresponding voltage output.

(2) The structure of the semiconductor varistor type

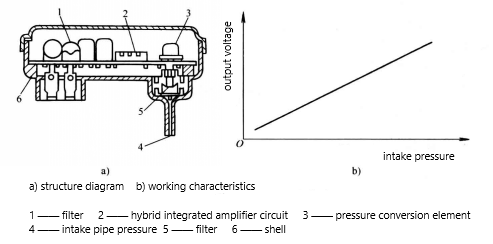

The composition of the semiconductor varistor type is shown in Figure 4. There is a silicon diaphragm in the pressure conversion element of the sensor, and the pressure and deformation of the silicon diaphragm will generate a corresponding voltage signal. One side of the silicon diaphragm is a vacuum, and the other side introduces the pressure of the intake pipe. When the pressure in the intake pipe changes, the deformation of the silicon diaphragm will change accordingly, and a voltage signal corresponding to the intake pressure will be generated. The greater the intake pressure, the greater the deformation of the silicon diaphragm, and the greater the output pressure of the sensor.

The semiconductor varistor type has good linearity, small structure size, high precision, and good response.

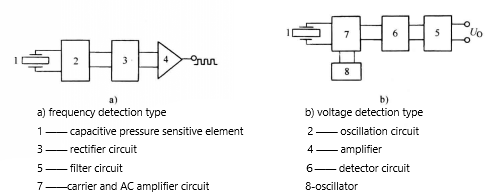

(1) The measuring principle of capacitive type

The capacitive type uses a diaphragm to form a pressure-sensitive element with a variable capacitance value. When the diaphragm is deformed by force, its capacitance value will change accordingly. The sensor measurement circuit will convert the change in capacitance into corresponding electrical signals. The measurement circuits of the capacitive type mainly include frequency detection and voltage detection, as shown in Figure 5.

1) Frequency detection type: The oscillation frequency of the oscillation circuit changes with the change of the capacitance value of the pressure-sensitive element, and the pulse signal with the frequency corresponding to the pressure is output after rectification and amplification.

2) Voltage detection type: the change of the capacitance value of the pressure-sensitive element is modulated by the carrier and AC amplifier circuit, demodulated by the detector circuit, and then filtered by the filter circuit to output a voltage signal corresponding to the pressure change.

(2) The structure of the capacitive type

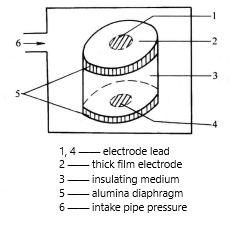

The schematic diagram of the capacitive type is shown in Figure 6. The aluminum oxide diaphragm and the hollow insulating medium form a capacitive pressure-sensitive element with a vacuum inside and connect a sensor hybrid integrated circuit. After the sensor introduces the pressure of the intake pipe, the aluminum oxide diaphragm deforms under the action of the intake pressure, causing its capacitance value to change. After being processed by the hybrid integrated circuit, it outputs an electrical signal corresponding to the change in the intake pressure.

Compared with the intake airflow sensor that plays the same role, the manifold absolute pressure sensor has no interference to the air intake, and the installation position is flexible (the manifold absolute pressure sensor can be installed far away from the engine intake pipe using the guidance of the vacuum tube). Therefore, the use of manifold absolute pressure sensors in modern engine electronic control systems is increasing day by day.

Popular Posts

Hot Labels

Popular Parts